Cotton Industry Sustainability: Key Environmental & Ethical Challenges

By Ben Tomkins | 19 December 2025

minutes to read.

Cotton is one of the most heavily traded commodities in the world. It’s the basis of many of the clothes we wear and the textiles we use every day, making it an essential material for the global apparel and textile industry.

But the market is changing, and the industry faces a number of sustainability and ethical challenges, which are increasingly drawing attention from consumers, regulators, and advocacy groups.

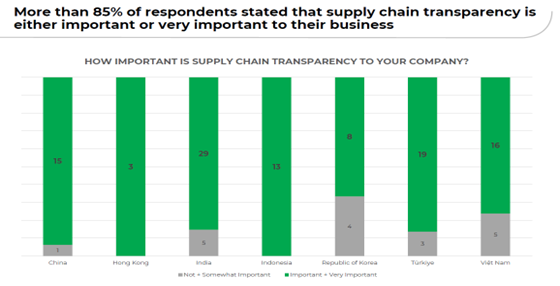

According to our latest industry research where we analyzed data from key cotton-producing regions, over 85% of the respondents consider supply chain transparency a critical priority, highlighting the growing demand for traceability and sustainability in cotton (source: Mintel, August 2025).

Failing to overcome these challenges could threaten not only the effectiveness of the entire supply chain, but also the reputation and future growth of businesses involved at every stage, from retailers to manufacturers and farmers.

This article dives into the main challenges for the cotton industry today, unpacking the causes, implications, and what is being done to address them.

Contents:

- Environmental challenges in the cotton industry

- Social and ethical issues in cotton production

- Traceability and forensic verification in cotton supply chains

- Paths to a sustainable cotton future

Environmental challenges in the cotton industry

Cotton is a commodity that is highly susceptible to environmental threats. Crops are vulnerable to pest attacks and can be decimated by severe weather events such as droughts and flooding, which are becoming more frequent with climate change.

In this section, we’ll examine the challenges of cotton’s water footprint, pesticide use, soil health, and ecosystem impacts, all of which are critical factors for sustainability.

1. Water footprint of cotton

Cotton is often referred to as a “thirsty” crop for its high water demands. Indeed, 157 gallons of water are required to grow the cotton used in one t-shirt.

This means that when consumers buy products like cotton apparel and sheets they are ‘using’ water from wherever the cotton was grown and produced.

The “Water Footprint in Cotton 2020–2024: A Global Analysis” study by the International Cotton Advisory Committee reveals that it takes 8,920 liters of water to produce 1 kilo of cotton.

Organic cotton is being favored by growers seeking to improve their environmental impacts. It offers a more sustainable alternative to conventional cotton, with a water footprint only 10% of the footprint of conventionally grown cotton.

2. Pesticide use and agrochemical impacts

Pest control is important to protect cotton crops from being devastated by insects, but pesticides threaten the quality of soil and water, as well as the health of biodiversity.

Cotton is the crop most heavily sprayed with chemicals in the world, leading to some commentators referring to it as the “dirtiest crop in the world”.

Cotton crops cover just 2.4% of the world’s cultivated land but use nearly 5% of the world’s pesticides (and 10% of insecticides).

Hazardous pesticides commonly used for cotton production are often found in nearby water resources. A study of rainwater in a Brazilian cotton region found that rainwater contained 19 different pesticides – 12 of which were used in cotton production.

3. Soil health, biodiversity and habitat loss

Conventional methods of growing cotton crops involve converting land for agriculture. This transformation of natural ecosystems causes significant habitat loss and can damage biodiversity.

Monoculture is the practice of growing the same crop repeatedly on the same land. Intensive farming in this way degrades the soil, stripping it of essential nutrients and reducing fertility over time.

Recycled cotton is being touted as an alternative to reduce land expansion and preserve wilderness areas through reusing cotton fibers. However, given that recycled cotton currently accounts for only 1% of total cotton production worldwide, it is likely that these adverse environmental impacts are set to continue for some time yet, unless efforts to increase recycling rates intensify.

4. Carbon footprint of cotton production

The cotton sector has a significant carbon footprint due to its emissions from fertilizers, machinery, and transport. Cotton production is responsible for the emission of 220 million tons of CO2 annually.

Clothing is a key commodity of what’s called “carbon leakage”, where the benefit of emissions-reductions in one country is offset by the pollution in another.

This means that when cotton products are imported, environmental pollution is imported along with it.

The cotton industry has taken steps to mitigate this damage. Since 1980, the US cotton industry has recorded a 25% reduction in GHG emissions.

Increased usage of organic cotton is contributing to this improvement. That’s because organic cotton tends to have lower emissions than conventional cotton. However, the lower yields and higher production costs of organic cotton present challenges for growers which may limit the pace of adoption.

Social and ethical issues in cotton production

The impact of conventional cotton farming extends beyond environmental issues to encompass significant social and ethical concerns as well. Poor labor conditions and social injustices remain barriers to ethical supply chains.

In this section, we assess the impacts on farmer livelihoods, labor rights, and value distribution, all of which are essential for the cotton industry’s social sustainability.

1. Farmer livelihoods and poverty

Cotton farming is a tough profession to make a decent living from.

- Cotton crops are at the mercy of weather patterns and growing conditions, making farmers especially vulnerable to crop losses and price volatility.

- Strong harvests will create excess supply, which pushes prices down.

- Clothing is a discretionary purchase for most consumers, which means that demand for cotton is sensitive to changes in households’ disposable income.

Farmers typically have the lowest profit margins in the cotton supply chain. In countries like India, smallholder farmers sometimes operate below the poverty line and face uncertain futures with insufficient social protection.

As we examined earlier, farmers can also face health risks from the chemicals used in crop protection, and laborers often toil in hazardous conditions with little protection. These factors reinforce the need for the cotton industry to adopt and maintain higher ethical standards across the supply chain.

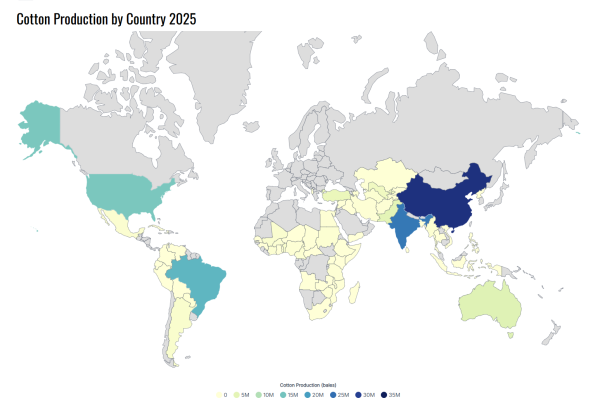

Source: World Population Review

2. Labor rights and child/forced labor

The exploitation of forced labor and child labor is a serious issue in cotton production. Of the 28 million people living in forced labor globally, nearly two-thirds are connected to global supply chains.

China is the world’s largest producer of cotton. The country produced 32 million bales in 2024, representing nearly 27% of total global cotton production. However, the country’s Xinjiang province has been accused of using forced and child labor in their cotton supply chains.

Despite the sustainability and ESG claims of many brands and retailers, the depth, opacity, and complexity of cotton supply chains make tracing and eliminating forced labor cotton extremely difficult.

Some retailers have found that Xinjiang cotton has been deliberately mislabeled in order to be sneaked into products sold on retail shelves.

The importance of forced labor as an issue in the cotton sector has given rise to a raft of legislation prohibiting goods associated with this practice, especially in key Western markets such as the US and EU.

3. Value distribution and fair compensation

Cotton supply chains involve up to a dozen steps, engaging many different manufacturers and suppliers, distributors and retailers.

Most of the profits from cotton production are captured by large, global apparel brands and fashion retailers. Intermediaries, such as ginning companies, gain lower profits from processing raw cotton fibers and often face intense competition themselves.

Traditional supply chains see farmers sell to ginners, who then sell to spinners, and so on through the supply network. However, cotton farmers are increasingly embracing new models to improve their situation, from direct trade to digital marketplaces.

- The direct trade model allows farmers to bypass some traditional intermediaries to deal directly with downstream partners, thereby strengthening their position and reducing their reliance on others.

- In some areas, individual farmers are grouping together in cotton cooperatives. By banding together, farmers seek to achieve stronger bargaining power, increased profits, and improved market access, reflecting the old adage of ‘strength in numbers’.

Oritain featured on Singapore Fashion Council's 'Fashion Futures'

Traceability and forensic verification in cotton supply chains

Recent years have seen a growing emphasis on transparency and traceability throughout the cotton industry supply chain. According to industry research, a significant majority of businesses are already adopting digital traceability technologies such as QR codes, blockchain-based systems, and other platforms.

Science and software tools provide solutions for cotton businesses to address the challenges and ethical issues of their industry. In this section we delve into cotton traceability and leveraging forensic science to authenticate product origin.

1. Importance of traceability for sustainability claims

Traceability plays an increasingly central role in supply chain risk management. If suppliers use unethical practices or knowingly subvert the law, brands and retailers suffer by association and their brand equity can suffer lasting damage.

Businesses that don’t substantiate their sustainability claims with credible evidence risk accusations of greenwashing – misrepresenting achievements for commercial advantage.

An EU commission report found that 40% of green claims made by companies were “completely unsubstantiated”. Over half made environmental claims that were “vague, misleading or unfounded”.

Cotton traceability programs are important to reassure brands and build consumer trust. Over two-thirds of adults believe that once a brand loses its trust, there’s no gaining it back. 40% of these people go further by trying to dissuade their friends and family to boycott these brands.

Effective traceability programs validate sustainability claims by proving that products match their labels and raw materials are sourced from their claimed origins.

2. Digital technologies and blockchain

Innovations in digital technology provide useful tools for businesses to gain better visibility over their supply networks.

- QR codes are placed on garments or bales, linking the physical product to digital records of its supply chain journey (from origin through ginning, spinning and so on). They provide instant transparency for consumers and allow manufacturers to verify the material's authenticity and source.

- GIS mapping uses satellite imagery and GPS coordinates to accurately map the specific cotton fields. This geospatial data is integrated into the product record, helping businesses verify sourcing claims and supporting standards for environmental impact and labor practices.

- Chain-of-custody platforms, often leveraging blockchain, secure data through a tamper-proof ledger that logs every transaction from farm to factory. This unbroken digital thread is important for reliable auditing, fighting counterfeiting, and ensuring regulatory compliance, especially as regulations become stricter.

3. Forensic science and origin fingerprinting

Forensic science provides stronger evidence of product integrity and authenticity than other traceability tools because it tests the physical product itself.

Scientific traceability is important for building trust. Too many fraudulent certifications have eroded trust in the cotton industry, making it increasingly difficult for companies to substantiate claims.

Studies show that many adults don’t trust ingredients or product claims unless they’re proven by science.

Using proven, reliable techniques, Oritain’s forensic verification can authenticate the original source location of cotton products and raw materials – in some cases pinpointing origin to individual farms.

This is achieved through defining Origin Fingerprints – unique chemical signatures linking cotton to specific geographic growing areas.

Oritain has mapped all core cotton producing areas of the world, creating an unmatched global database which can be used to test cotton products throughout the supply chain across diverse product ranges and industries.

The scientific robustness of Oritain’s methodology mitigates the risk of brands believing they’re procuring a compliant commodity, only to discover it’s sourced illegally or unethically.

4. Regulatory compliance: UFLPA, EUDR & due diligence laws

Cotton businesses face a range of reporting and due diligence requirements to comply with legislation targeting forced labor, deforestation, and other social and environmental threats.

Foremost among these is the Uyghur Forced Labor Prevention Act (UFLPA), enacted by the US government and mandating that importers must prove their goods are free of forced labor or face seizure and penalties.

Under the UFLPA, forced labor compliance has become critical for businesses seeking to trade in the US. But other geographies around the world are taking a similar path, including Canada’s Modern Slavery Act and the EU Forced Labour Ban.

Failing regulatory compliance means losing market access, an outcome which could cost fashion brands millions in lost sales and damage long-term brand value.

The EU Deforestation Regulation (EUDR) prohibits products sourced from deforested land from being traded in the EU. While not directly affecting cotton, the legislation will impact brands whose products include leather, and indicates a wider regulatory shift that cotton businesses should watch closely.

Cotton businesses trading in EU markets will also need to abide by the growing number of sustainability regulations being introduced, including the Corporate Sustainability Due Diligence Directive (CSDDD) and Corporate Sustainability Reporting Directive (CSRD).

5. Challenges and best practices for implementing traceability

Follow the tips below to help evaluate, improve, and maintain traceability within your supply chain.

i. Understand the regulatory landscape

- Make sure you’re aware of and compliant with all the key local and global laws affecting the cotton and textile industry.

- Introduce measures to ensure that no part of your operations involves forced labor or human rights violations.

- Stay updated on evolving regulations, such as forced labor prevention acts and sustainability directives, to avoid penalties and maintain market access.

ii. Assess your traceability strategy

- Evaluate whether your current methods can objectively and accurately trace the origin of your cotton.

- Review whether you’re over-reliant on paper trails and certifications as your main methods of traceability.

- Consider integrating advanced verification methods, such as forensic verification, to independently validate origin claims and strengthen your traceability efforts.

iii. Enhance visibility into your raw materials

- Ensure your employees and subcontractors are committed to the same standards of behavior as your company.

- Introduce tools to identify nodes in your supply chain that are at risk of blending and mislabeling.

- Verify early in the supply chain to detect and address risks before they escalate.

iv. Provide chain of custody documentation

- Ensure you have well-documented records of purchase orders, invoices, and shipping documents that trace your cotton back to its source.

- Verify the accuracy of these documents using the Oritain origin verification platform.

- Build a verified buyer-supplier network to strengthen trust and accountability across the supply chain.

See more about how to integrate sustainability, resilience and transparency in supply chains.

Paths to a sustainable cotton future

Building a more equitable and successful future comes from turning challenges into opportunities. In this final section, we’ll examine the strategies, innovations, and partnerships driving long-term sustainability.

1. Organic, regenerative & recycled cotton practices

When posed the question of “Is cotton sustainable?”, many industry analysts would say “no” – but a range of innovations are promising a more sustainable future ahead.

Organic cotton has lower carbon emissions than conventional cotton, more efficient water use, reduced reliance on pesticides, and improved soil health through crop rotation.

The Regenerative Cotton Standard was introduced to improve the vitality of the cotton ecosystem. This voluntary standard has been adopted by many small-scale farmers to grow cotton using regenerative farming methods that restore soils and increase resilience to climate change.

Recycled cotton attempts to minimize the negative impact of conventional cotton growing by reclaiming and reusing cotton fibers. This helps to reduce land expansion and supports the preservation of wilderness areas.

The cotton industry is also working to address the adverse impacts of pesticide use, and claims to have reduced insecticide use by 95% since 1993.

2. Market and policy interventions

Farmer livelihoods are set to improve through the introduction of income protection, subsidies, and financial incentives.

Price risk management helps cotton farmers cope with volatile global commodity prices by locking in a minimum price for their yield. This ensures a level of income stability to improve farm viability and community well-being.

Subsidy reforms aim to eliminate trade-distorting subsidies from wealthy nations that depress global prices. If successful, these reforms are expected to raise global prices and deliver higher incomes for farmers, potentially by up to 30-40% in some regions.

Financial incentives encourage farmers to adopt more sustainable and regenerative cotton methods. These include payments or grants to cover the costs of transition and lessen the financial risk to farmers.

3. Consumer engagement and ethical purchasing

Motivated by ecological and social concerns, consumers are driving demand for certified and traceable cotton. These consumers value transparency and actively seek information about how products are made and what environmental impacts result.

Cotton certification schemes provide reassurance to consumers by verifying that cotton is produced to specific environmental and ethical standards. Some of the main certification programs include:

- Global Organic Textile Standard (GOTS): Ensures products are made with certified organic materials.

- OEKO-TEX: Tests and certifies textiles for harmful substances to ensure product safety.

- Better Cotton Initiative (BCI): Promotes sustainable cotton production practices.

- US Cotton Trust Protocol: Focuses on measurable sustainability goals, including land use, soil carbon, water management, and energy efficiency.

- Fairtrade: Guarantees cotton farmers receive a fair price for their crops.

- World Responsible Accredited Production (WRAP): Certifies that facilities comply with ethical, safe, and lawful manufacturing practices.

- Responsible Brazilian Cotton (ABR): Certifies farms in Brazil to meet agricultural, environmental, social, and economic criteria.

- Cotton made in Africa (CmiA): Focuses on improving the living conditions of African smallholder farmers while protecting the environment.

Studies indicate that sustainable cotton is viewed positively by apparel consumers. But brands must recognize that consumers do not merely take product claims at face value. These must be verified in order to be trusted and encourage purchase.

Verified information on product origin, authenticity or manufacturing processes, clearly presented on labels, strengthens consumers’ purchase intentions.

4. Oritain’s role in advancing cotton traceability & sustainability

Oritain is a pioneer in the field of forensic origin verification. This unique combination of cutting-edge science, advanced technology, and specialized services delivers the highest levels of precision to support cotton traceability.

Our isotopic testing is so reliable it is also employed by the US Customs & Border Protection agency to verify the provenance of cotton products imported into the United States.

We work alongside many of the world's leading cotton brands, retailers, manufacturers, and suppliers. Our forensic methodology has helped these businesses achieve regulatory compliance, reduce reputational risk, and verify the provenance of their products for nearly 20 years.

We analyze cotton samples from throughout the supply chain to provide assurance of authenticity to global cotton brands including Supima and Lacoste.

Our extensive testing programs verify the integrity of raw material cotton for leading textiles and apparel manufacturers such as Ramatex and Yunus.

Oritain continues to innovate and develop our cotton capabilities to support a more sustainable and ethical future for everyone.

As it evolves to meet the demands of consumers and other audiences, the cotton industry faces a number of sustainability and ethical challenges. But innovations in traceability and origin verification, alongside improvements in supply chain management, are set to protect workers and deliver better products for consumers into the future.

Learn more about the work Oritain does with cotton businesses across the world by speaking with one of our team.

Disclaimer: The information provided in this document does not and is not intended to constitute legal advice. Instead, all information presented here is for general informational purposes only. Counsel should be consulted with respect to any particular legal situation.