What is Cotton Traceability & Why Does it Matter?

By Rupert Hodges | 18 August 2025

minutes to read.

Cotton is one of the most traded commodities in the world, with 114 million bales produced across 2023/2024. But fashion and apparel businesses are under increasing pressure from regulators, consumers, media and other audiences.

Cotton traceability has become an important tool to enable these businesses to verify the integrity and authenticity of their products.

In this guide, we’ll unpack cotton traceability to provide everything you need to know – how it works, why it matters, and how you can implement it successfully in your business.

Contents:

- Understanding cotton traceability

- Why cotton traceability matters

- How cotton traceability works

- Overcoming common challenges

- Managing your cotton supply chain

1. Understanding cotton traceability

In this section, we’ll define the concept of traceability and explore its relevance within the cotton, fashion and textile industries.

Definition & scope of traceable cotton

Cotton traceability is the process of tracing raw cotton or cotton goods throughout production, from material sourcing to retail sale. This production involves a number of stages as the cotton advances from point of origin through the supply chain.

Cotton is grown in over 75 countries around the world but possesses different characteristics depending on growing location. With the right technology solutions in place, this makes it a highly traceable commodity.

Raw cotton can be analyzed using scientific methods to identify where in the world the cotton was grown. Specific sourcing locations can be determined based on unique environmental elements within the cotton itself.

That means cotton from China can be clearly distinguished from cotton grown in the United States, for example.

Effective traceability systems allow fashion brands and retailers to trace their cotton products through every step of this supply chain (often referred to as tiers). Any issues with their product can be pinpointed to specific stages and specific vendors, making it easier to resolve them.

How fabric traceability works

Cotton is a hugely versatile material used in a wide range of products from clothing and sheets to textiles and towels. To make these products, cotton fibers are spun, woven and otherwise processed to make different cotton fabrics.

Each of these fabrics can be traced back to specific stages of manufacture through cotton fabric traceability.

Once the fiber leaves the farm it passes through many stages of processing and refining. This includes:

- Harvesting

- Ginning

- Cleaning

- Spinning

- Weaving

- Knitting

- Dyeing

- Distributing

- Selling

Finished cotton goods can be traced through the supply chain regardless of any cleaning, blending, dyeing or other processing that has taken place.

2. Why cotton traceability matters

This section explores why cotton traceability is critical for modern supply chains. We’ll examine the impact of cotton regulation and compliance, the growing importance of sustainability and ESG, and the role of traceability in maintaining product integrity.

Compliance & risk management

Cotton and fashion businesses are facing a wave of new and evolving regulations. These have increased demands on leaders, and many are struggling to keep up. 43% of chief ethics and compliance officers (CCOs) say new regulatory requirements are their biggest compliance challenge.

Forced labor laws, most prominently the UFLPA, but also the imminent EU forced labour ban and Canada forced labor law, have had a huge impact on the sector. Forced labor compliance now means that businesses must now prove that no cotton used in their products is sourced from areas of the world linked to forced or child labor.

Regulators also identify that traceability documentation supplied from vendors is often insufficient to substantiate sourcing.

The penalties for noncompliance include shipment seizures, financial penalties, loss of market access, and reputational damage.

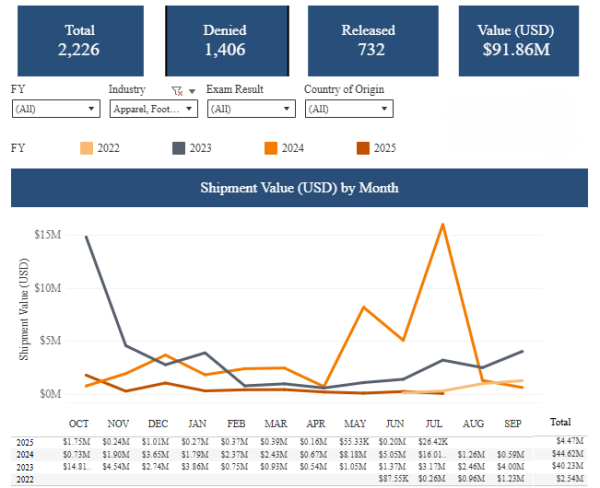

Since the UFLPA was introduced, more than 2,200 shipments of apparel, textiles and footwear goods, worth nearly $92 million, have been detained. Of these CBP detained shipments, 62% were denied entry into the United States.

Businesses operating in the EU also face enhanced environmental legislation. This includes the Corporate Sustainability Due Diligence Directive, where businesses must identify and mitigate any adverse environmental and social effects from their operations. Importers must review the accuracy of traceability information received from vendors.

Most legislation requires businesses to have oversight throughout their supply chain. This includes the processes and practices of upstream manufacturers and suppliers that source the materials a company uses to produce products. If suppliers are in contravention of regulation, brands will also be liable.

Therefore, verification of the sourcing origin claims for cotton is critical to ensure products and raw materials are free from illegal, unethical or unsustainable practices. It allows fashion brands to minimize risk and puts them in a much stronger position to meet compliance requirements.

Sustainability & environmental stewardship

ESG (Environmental, Social and Governance) will be a significant driver of future business success. Investors will increasingly fund businesses that have credible ESG credentials, robust processes around social and environmental practices, and are less susceptible to regulatory capture.

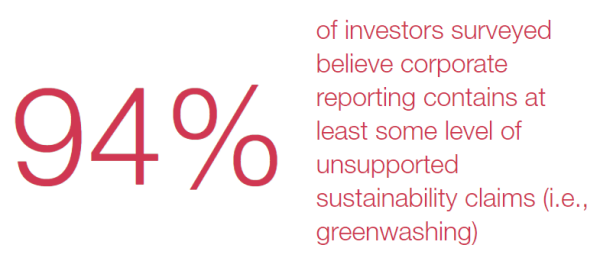

But businesses that don’t substantiate their ESG claims with credible evidence risk accusations of greenwashing – misrepresenting ESG achievements for commercial advantage. An EU commission report found that nearly half of sustainability claims made online were judged to be false or deceptive.

Source: PwC Global Investor Survey 2022

Consumers, regulators and other markets are all growing wiser about greenwashing. Brands now need to back up sustainability and ESG claims with evidence.

Traceability programs support sustainable sourcing and impact reduction by providing businesses with oversight of where their raw materials are sourced from. It delivers assurance that their products are free of association with forced labor, deforestation, or other such practices.

Cotton supply chain traceability empowers brands to operate more sustainably. By identifying areas of poor practice, they can implement corrective measures to reduce impact and protect natural ecosystems.

Sustainability and traceability strengthen brand reputation through enabling businesses to credibly assure consumers of their green credentials.

Quality assurance & authenticity

There is a global crisis of trust in the food we eat, the clothes we wear and the products we buy, underlined by high-profile consumer scandals. Fraud and unethical practices erode the integrity of brands and harm vulnerable people, animals and ecosystems across the globe.

It also costs industries billions of dollars every year and exposes companies to serious reputational risk relating to fraud, illegal working practices and environmental damage.

Trust is imperative for every company. Studies show that consumers buy significantly less from a business that has lost their trust.

Traceability is integral to reduce cotton supply chain risks, build trust, and protect reputation. It ensures the authenticity and safety of products by verifying material origin and integrity.

This assures brands that their processes are robust and assures customers that the product they’ve purchased is what it claims to be.

In some sectors where sourcing origin determines product quality – industries such as cotton, coffee and wine – this quality assurance is essential to maintain premium pricing, competitive advantage and customer trust.

3. How cotton traceability works

This section outlines some common traceability technology and tools used in the verification of cotton and fashion products, from forensic science to DNA markers and digital platforms.

Forensic fiber fingerprinting (isotope analysis)

Forensic isotopic analysis is a scientific form of verification that is like the CSI of supply chain traceability. Forensic isotopic testing verifies product origin by evaluating chemical properties that relate to origin within a raw material against a reference database. The process is similar to how forensic detectives use human fingerprints to identify criminals.

This is called “Origin Fingerprinting”.

Our environment is made up of elements which are specific to the local climate and geological conditions. Animals, plants and other products take up elements from soil, water and feed, according to where in the world they are grown, reared, or made.

Forensic chemistry tells us the precise range and quantity of elements present in a product. These link back to the unique environmental conditions of the sourcing area, including soil composition, climate, altitude, and precipitation.

The “Origin Fingerprint” of a specific product and origin population can be defined by a collection of chemical characteristics that form a distinguishable pattern.

Like human fingerprinting, a reference database of Origin Fingerprints can be developed which can then be used to audit products throughout the supply chain to clearly differentiate the legitimate from the fraudulent.

In the case of traceable cotton, forensic analysis can verify whether cotton fibers are authentic to their claimed origin, verify if they come from regions with high risk of forced labor, and corroborate or challenge other traceability sources.

The Oritain cotton traceability solution combines our forensic methodology with comprehensive testing programs and digital platforms. It is robust enough to be admissible in court, and unlike other traceability methods it is highly resistant to being tampered with, replicated, or destroyed.

DNA tagging & molecular markers

DNA tagging is a type of technology used to mark and verify fibers at source. Molecular identifiers are applied to cotton fibers at the earliest stages of production. These microscopic markers function like DNA barcodes to enable identification and verification.

Using this tool effectively for cotton traceability relies on the accurate application and detection of the marker or tracer. It is also often applied at the ginning or spinning stages, so does not represent the full end-to-end cotton value chain from dirt to shirt.

Because this method relies on human interaction, it can be susceptible to error. The integrity of testing depends on the active participation of all parties in the supply chain.

Digital traceability platforms (blockchain & data systems)

Blockchain and AI are digital traceability tools that use real-time tracking and monitoring to automate data collection and sharing in global supply chains.

Blockchain records and verifies transactions using cryptography within a decentralized network. It provides a digital audit trail for compliance but doesn’t physically inspect or verify the authenticity of products in the system.

That means the reliability of blockchain in product verification is completely dependent on the accuracy and transparency of the data entered into the system.

AI and machine learning analyze supplier data to identify any financial ties to banned entities. It cross-references data from multiple sources to confirm product origin claims.

However, the system still relies on supplier information and cannot guarantee product integrity or protect brand reputation. It can flag potential fraudulent activities through data analysis but cannot guarantee prevention.

4. Overcoming common challenges

In this section we’ll uncover why traceability can be complex to implement for businesses. We’ll examine some common challenges, including fragmented supply chains, insufficient or inaccurate data, and financial and operational barriers.

Supply chain fragmentation

Supply chains are integral to business success, but their complex nature makes implementing robust traceability programs a challenge.

Part of the problem is that supply chains have become longer and more disjointed. Businesses are operating multi-tier supplier networks which outsource critical manufacturing functions. These functions are often dispersed right across the globe.

Unlike the global food supply chain, cotton has no harmonized system of compliance nor long history of high-quality traceability.

Many brands only engage with their Tier 1 suppliers. Most suppliers have no relationship with others in the network. This leaves large parts of the supply chain – especially raw material sourcing – unchecked. And these blind spots can mask practices which could endanger the business.

Despite this fragmentation of supply networks, most legislation requires brands to have full oversight of not just their own processes and operations, but also those of all upstream and downstream partners.

This situation creates a challenge for brands, where traceability programs must work harder to accurately trace and authenticate the origin and journey of their products and raw materials.

It’s not enough to have transparency on what’s happening in your supply chain – you need to have a method of authenticating that information.

Knowing the true origin of your products increases the strength of your supplier relationships. Cotton traceability helps build more robust supply chain networks and helps reduce the risk of catastrophic disruptions for fashion brands.

Data integrity & verification

The volume and type of information that businesses collect and manage can vary widely. The processes they have, the systems they use, and the governance they apply all influence how accurate and trustworthy the information is.

But reliability and thoroughness of data is essential for effective traceability.

This is particularly important for cotton, which is often traded with very limited documentation. Signed paperwork or vendor self-declarations – sometimes incomplete or subjective – are often the only proof of origin provided. Even AI and mapping solutions can fail to provide authentic data if this initial input is flawed.

Without independent verification, the information circulating through the supply chain only perpetuates the inaccuracies. This leaves brands to steer through the murky waters of cotton traceability relying on trust alone.

Forensic testing provides a cotton traceability solution that bolsters accuracy and trust. Studies show that many adults don’t trust ingredient or product claims unless they’re proven by science.

Scientific verification tests the physical product itself, providing stronger, more reliable evidence than many other traceability tools.

Cost & infrastructure barriers

The cost and resource requirements of traceability programs can be barriers to implementation.

Technology solutions like blockchain and AI require significant investment in data and technology infrastructure. SME businesses in the supply chain may not have the funds or see the immediate payoff to introduce such tools.

Added to this are the ongoing costs of gathering and managing all that data. These expenses are not always easy to pass on to consumers, which leaves the businesses absorbing the financial hit.

On the operational side, cotton frequently moves through numerous intermediaries, including ginners, spinners, weavers, dyers, and garment makers – sometimes even across countries. Cotton from diverse origins can easily be blended at any stage, making it difficult to maintain a clear and verifiable record of origin.

The lack of industry-wide standards can also hamper traceability efforts. Suppliers, especially smaller operators or those in developing countries, might resist this due to concerns over complexity, disruption, or exposure of trade secrets.

However, many traceability solutions, like forensic testing, can be seamlessly integrated into existing operations and require minimal or no downtime. And the cost of implementation is often far less than the financial impact and reputational damage accrued from transacting fraudulent or noncompliant goods.

5. Managing your cotton supply chain

In the final section we’ll discuss some practical steps businesses can take to embed a successful traceability program and look at how traceability works across the broader textile industry.

How to ensure material traceability in the cotton supply chain

There are a number of practical strategies that brands, suppliers and partners can use to build an effective cotton traceability program.

1. Map your products and supply chains. Identify the raw material suppliers you use together with where they are based and which countries they operate in. Define the relationships between your suppliers and their partners.

2. Collect reporting data from your internal systems and suppliers including production dates, quantities, export details and suppliers involved.

3. Establish a traceability team to embed processes across your business, manage governance and report to leadership.

4. Create corrective action plans for risk management when issues are identified, including timeframes and follow-up.

5. Engage external partners for third-party verification, such as Oritain scientific analysis. Implement new technology platforms to close information gaps.

6. Set supplier objectives, codes of conduct, staff training sessions, onboarding programs and communication plans. Schedule regular on-site audits of supplier premises.

What is traceability in the textile industry?

The fashion and apparel industry uses a diverse range of materials in their products, including both natural and synthetic fibers. As well as traceable cotton, traceability programs can also be introduced for leather, silk, denim and wool traceability.

For products like denim, which is one of the largest users of water in the fashion industry, traceability is an important tool for proving sustainable production practices. American fashion brand Cone Denim have worked with Oritain since 2020 to verify their ethical material sourcing.

Wool is a material widely used in a range of garments due to its warmth, durability and comfort, but wool quality is highly dependent on where it comes from. Better quality wool sells for premium prices. Traceability enables wool producers and brands to verify the origin of their premium products to consumers.

Traceability will also expand in scope to cover emerging products such as blended fabrics, where different raw materials are sourced from vastly different parts of the world. Each of these materials will need to be assessed and verified to ensure compliance with forced labor, deforestation and other legislation.

(Image credit: Vecteezy)

For more information on how to build an effective cotton traceability program that meets your compliance, sustainability, and business needs, contact us to speak with a member of the Oritain team.

Our experienced global team work with some of the world’s leading cotton and fashion brands. We’d love to work with you too.

Disclaimer: The information provided in this document does not and is not intended to constitute legal advice. Instead, all information presented here is for general informational purposes only. Counsel should be consulted with respect to any particular legal situation.