What is Supply Chain Traceability? Guide to Understanding End-to-End Visibility

By Rupert Hodges | 15 September 2025

minutes to read.

Supply chains are the essential veins and arteries that keep the business pumping. Without them, raw materials aren’t sourced, products aren’t manufactured, retailers have nothing to sell, and consumers have nothing to buy.

But within today’s increasingly lengthy, opaque and fragmented supply chains, hidden blind spots are waiting to trap the unwary and the unprepared.

Supply chain traceability allows organizations to gain invaluable insights into their processes. Through effective traceability programs, leaders can identify potential issues proactively and ensure compliance with regulatory standards.

This is your essential guide to supply chain transparency and visibility.

Contents:

- Understanding supply chain traceability systems

- Main types of traceability systems

- Basic rules and regulations

- Simple technology options

- Getting started with traceability

- See it in action

- Next steps

1. Understanding supply chain traceability systems

In this first section, we’ll begin by defining the concept of supply chain traceability and examine its relevance for businesses today.

What is a traceability system?

A traceability system is a program which records where products come from and where they go. This begins with the source of raw materials and continues through until sale to end users.

All products pass through a number of steps as they are produced. Each step in this supply chain involves different processes and is often handled by different people. More complex products require a greater number of steps and therefore pass through a higher volume of hands.

For example, the production of cotton clothing and textiles goes from the cotton farm, through ginning, spinning, weaving and dyeing, to manufacture, distribution, retail and sale. Cotton requires a very complex but traceable supply chain.

Supply chain traceability systems track the progress of a product throughout these steps. It provides essential information for both manufacturers and brands on the integrity, authenticity and market-readiness of their products.

Why it matters for your business

Supply chain traceability is important because it provides businesses, customers and other audiences with assurance of product quality and integrity. This is essential to support business growth and protect consumer wellbeing.

Traceability helps ensure products being sold match the expectations of the brand and the customer. That’s essential for maintaining trust in the market. Consumers buy significantly less from a business that loses their trust, and 4 in 10 customers no longer purchase from a company due to lack of trust.

A high-performing traceability system can identify when fraudulent practices may have occurred. This includes supply chain fraud such as counterfeiting, substitution or blending. In certain sectors, such as food and pharmaceuticals, these unethical practices could result in serious threats to consumer health and safety.

Effective traceability also reveals the true sourcing location of raw materials, such as the coffee beans used by global coffee brands or the wool used by fashion houses. This is critical for businesses to prove compliance with social and environmental legislation, such as forced labor and deforestation regulations.

Supply chains are inherently lengthy and complex, but introducing systems to improve supply chain visibility help to manage processes and minimize risks.

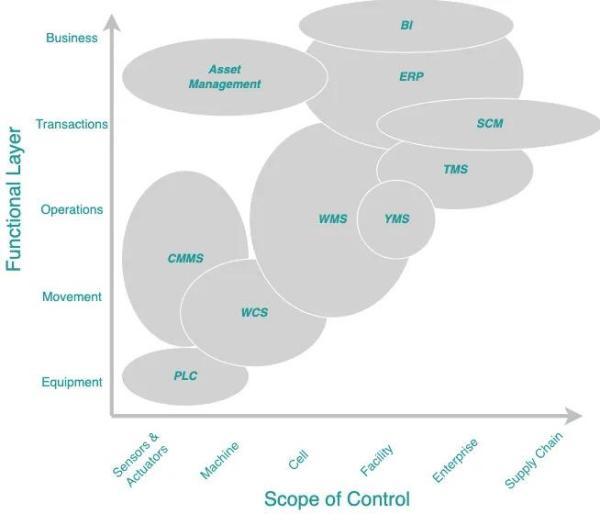

Source: Medium: The Fragmentation of Supply Chain Information Systems

2. Main types of traceability systems

Next up we’ll discuss the main categories of traceability systems to help you decide on the particular system that’s best for your business.

Forward traceability

Forward traceability involves tracking materials forward through the supply chain as they move toward the customer. Typical examples of this would be tracking the location of products currently being distributed or identifying the retail stores where products were sold to end customers.

This information helps brands inform distribution schedules and ensure shipments will reach their destinations when expected in order to meet critical deadlines.

It is also instrumental in situations where products must be recalled due to safety concerns, enabling businesses to quickly identify and alert affected retailers.

Backward traceability

Backward traceability involves tracing finished goods back through the supply chain to their source. Examples of this would be tracing products to a specific stage of manufacture or verifying the original sourcing location of raw materials.

If a product defect or other issue is identified, traceability enables businesses to pinpoint where in the supply chain the issue occurred. It’s then easier and faster for the business to investigate and introduce corrective measures.

Verification of product origin enables brands to prove that their products are authentic (for example, that their sheets are 100% Egyptian cotton) and made responsibly and sustainably (for example, that their cocoa beans aren’t sourced from deforested land).

End-to-end traceability

End-to-end traceability combines both backward and forward traceability for full visibility of the entire supply chain. This is the most comprehensive traceability system and provides businesses with the greatest transparency and control over their operations.

Every program, every process and every supplier is clear, together with the impact each makes.

Using this method, businesses are equipped with data from every stage of production. Enhancements can be introduced, remedial actions implemented, and efficiencies improved. Suppliers involved with each stage can readily be identified for necessary communication or management.

End-to-end visibility for supply chains ultimately enhances quality, optimizes efficiency, and builds greater stakeholder confidence.

3. Basic rules and regulations

This section provides a useful high-level overview of some key laws and standards that apply in different parts of the world, and their impact on supply chains.

Key US requirements

Complying with federal regulations is essential for any company wanting to conduct business in the United States. Companies importing goods into the US will need to meet stringent requirements to avoid their shipments being stopped at the border.

Proving the responsible sourcing of cotton products is compulsory under the Uyghur Forced Labor Prevention Act (UFLPA). Businesses must conduct sufficient due diligence, auditing, and traceability to enable forced labor compliance and ensure that their supply chains are clean of cotton from regions known to employ forced labor.

Since the UFLPA was introduced, more than 2,200 shipments of apparel, textiles and footwear goods, worth nearly $92 million, have been detained. Of these, 62% were denied entry into the United States.

The Food Safety Modernization Act (FSMA) requires US food facilities to proactively introduce measures to prevent product contamination. This encompasses the entire supply chain, from farm to table, making product traceability essential.

Consumer safety is also at the heart of the Drug Supply Chain Security Act (DSCSA). This aims to prevent counterfeit or harmful drugs from reaching consumers, requiring pharmaceutical companies to have greater oversight over their entire supply chain.

Global standards to know

Several important regulations concerning sustainability and traceability govern businesses trading in geographies outside the United States. Each of these requires businesses to have a deep understanding of their supply chains. Traceability systems will be essential for compliance.

In the European Union, the EU Deforestation Regulation (EUDR) prohibits importing into or exporting out of the EU products associated with deforestation. It covers commodities including cattle, coffee, cocoa, wood, rubber and soy.

The EU has also introduced the EU forced labour ban. Similar in scope to the UFLPA, this prohibits the trade of products made with forced labour. The EU Commission will publish guidelines for compliance in mid-2026, before enforcement begins from late 2027.

Other countries also have their own forced labor legislation, including Canada’s Forced and Child Labor Act.

The environmental impacts of production are increasingly being addressed in legislation like the Corporate Sustainability Due Diligence Directive (CSDDD). This requires companies to carry out periodic assessments of processes, policies, and procedures throughout their supply chains.

Digital Product Passports will be rolled out in the EU from 2026. These require all products traded in the EU to have a digital record detailing the product’s environmental footprint from raw material sourcing to production.

4. Simple technology options

In this section we delve into the detail of some supply chain traceability solutions available to help your business get started without heavy investment.

Barcodes & QR codes

Basic supply chain traceability can be introduced using barcodes and QR (Quick Response) codes. These scannable codes are generally printed on or attached to product packaging like cartons or boxes, enabling easy batch and item tracking.

This option is widely used to manage the distribution of products from manufacturing locations to retail outlets across the world.

However, it must be remembered that this method effectively traces the packaging only – not the product specifically. This makes it less useful for identifying and resolving issues to do with product integrity or source material.

RFID & sensors

RFID (Radio Frequency Identification) and sensors use wireless tags and environmental monitors for traceability. RFID tags have unique identifiers to provide real-time data on products.

When combined with sensors, this technology can monitor conditions like temperature, humidity, or location during a product's journey through the supply chain.

The main drawback of this method is that its efficiency is reduced as the product moves further out of scanner range. These tools also require a slightly higher level of expense and technical acumen to implement.

Digital ledgers (blockchain)

Details of product manufacture and transactions can be managed through digital ledgers. These systems record timestamped data on the movement of goods through the supply chain.

Unlike traditional ledgers, digital ledgers are decentralized, enabling users to access the full information from any number of terminals. Updates are instantaneous, allowing for real-time transaction processing.

Blockchain is a type of digital ledger where data is stored in sequential blocks. This software can track the journey of goods from their source to the end consumer.

However, while this provides a digital audit trail for compliance, it doesn’t physically inspect the products. That means the accuracy of product information is only as good as the information entered into the system.

5. Getting started with traceability

Enough theory, it’s time to get practical! This section provides some actionable first steps for non-experts to help you get underway and gain confident with traceability programs.

Map your supply chain

Improving your supply chain traceability begins with mapping and governance. This goes beyond your immediate, tier 1 suppliers. It requires you to identify who your suppliers are working with, where they operate, and how they manage their operations.

This is essential because many pieces of legislation hold brands and retailers accountable for the practices of all their manufacturers and suppliers, as well as their own. Any incidents of product fraud or unethical or unsustainable behavior can jeopardize the entire supply chain's integrity.

To gain this transparency, map out your broader supply chain. This will help you establish all the partners involved and the relationships between them. For each partner, define their locations of interest, key personnel, employment practices, ESG (Environmental, Social, and Governance) footprint, and other vital information.

Formalizing this provides the transparency necessary to quickly address any issues that may emerge down the line.

Work with your suppliers

Once you've mapped your supply chain, set objectives and KPIs for your suppliers and introduce a formalized auditing and testing program.

Create a supplier engagement plan including clear objectives, expectations and accountability for suppliers. This could include targets for carbon emissions, schedules for workplace inspections, and formalized sourcing and employment policies.

Establish a supplier code of conduct, arrange staff training and embed your requirements into new supplier onboarding programs. This clear communication removes ambiguity and enables you to act decisively if remedial actions are needed.

Verify the accuracy of the information provided by your suppliers using product testing grounded in scientific analysis. To understand what is scientific traceability, platforms like Oritain test the products or raw materials themselves, delivering highly precise results and quickly identifying any discrepancies or potential issues.

Be aware that there is a significant difference between traditional traceability vs. scientific traceability. The needs of your business will influence the best solution for you.

Implementing testing programs and on-site audits are critical for achieving the transparency and traceability you need throughout your supply chain. Remember, any breaches by your suppliers can endanger your business too.

Pick easy tech steps

With your supply chain mapped and supplier engagement formalized, you’re ready to introduce traceability software. Focus on one tool initially and build upon this later when you’re more confident with the process and the outcomes you need.

Begin by assessing the suitability of the current reporting tools you have available. Do they capture all the information you need to both ensure product quality and meet regulatory requirements? Identify any reporting data missing from your systems or documentation gaps from your suppliers.

Invest in data management and reporting software that aligns with the scale and maturity of your business. You needn’t invest in costly enterprise level software if your business is an SME or in early growth stages.

Leverage third-party product verification to support your risk mitigation. Engaging an external partner like Oritain for scientific analysis and official certification can significantly enhance your compliance and trust.

Introducing these traceability tools will help to close any knowledge gaps and improve your overall supply chain management.

6. See it in action

Now it’s time to see this in action. This section summaries some real-world examples showing how organizations in different industries implemented supply chain solutions to address key challenges and improve their business.

Fashion & textiles example

Supima is a world leading premium cotton brand representing hundreds of US growers of American Pima cotton. This rare and premium fiber is often referred to as the 'World's Finest Cottons'.

In 2018, Supima began working with Oritain to authenticate its fibers using forensic science verification of its traceability system. To complement this, Supima partnered with TextileGenesis in 2023 to replace their existing documentary chain of custody.

After bale purchases are recorded and verified with TextileGenesis, material tests are carried out at various stages of production and retail by Oritain.

Both solutions offer distinct and complementary advantages. Oritain uses forensic chemistry and data science to accurately verify product origin; TextileGenesis provides process connectivity through a digital ledger framework.

This seamless and comprehensive traceability solution provides Supima with total assurance of the integrity of their supply chain.

Food & drink example

Nescafé Origens do Brasil is a premium coffee range imbued with the unique qualities only found in special regions of Brazil. It's part of Nescafé’s commitment to supporting sustainable practices and responsible sourcing.

To bring this to life for discerning coffee drinkers across the world, Nescafé needed to capture the essence of its origin – and prove it to consumers and retailers.

Through world-leading forensic science, Oritain can verify coffee back to specific points of origin. These growing locations can in some cases be defined as precisely as individual farms.

Nescafé worked with Oritain to assure consumers that their specialty coffee is authentic to its origin – helping them make an informed choice to support a brand committed to transparency, sustainability, and authenticity.

Healthcare example

Cytiva is a life sciences company renowned for their premium HyClone™ FBS products. These are used by businesses in a range of research, biopharma and gene therapy applications.

Serum from certain geographic areas is required by customers to maintain specification and regulatory standards - as such they can command a price advantage for manufacturers.

Origin verification is critical to ensure that label descriptions are an accurate representation of product origin – and that customers can be assured of the product contents.

Cytiva has worked with Oritain for nearly a decade to analyze FBS samples from different regions. This scientific origin verification is combined with traceability documentation to define the entire journey of a serum product, from collection at site of origin through manufacturing and distribution, providing a full picture of a product’s history.

7. Next steps

In this last section we’ll offer some final advice and look at some simple pathways you can follow to learn more.

Choosing your first project

Bringing a traceability program to life can feel challenging. It requires an implementation roadmap with clear objectives and outcomes.

Start small and build upon this as you gain confidence in your processes and results. Select a specific product line for your first project. This could be an emerging product you have greater flexibility to support, or a legacy product for which you have established benchmarks to assess your progress against.

If you have a product with known supply chain issues, introducing a traceability program could provide essential learnings while addressing the causes.

Your focus in the first year is to establish a baseline and identify key risks. Start with verifying supplier claims on selected finished goods. Benchmark supplier performance to improve transparency.

Next, look to scale and embed your traceability program deeper into your company’s operations. Expand testing across more suppliers and geographies and increase the frequency of product testing.

After this you can progress to full-scale integration, implementing a comprehensive global traceability framework. This will continuously monitor all suppliers and product lines and proactively prevent risks before they escalate.

Where to learn more

Oritain provides a range of useful material to help businesses on their journey towards supply chain traceability. These include guides, reports, articles, and on-demand webinars.

Our blog is updated regularly with insights, analysis, and latest market news from our leading science, traceability, and product experts.

Listed below are links to some of our most popular supply chain material.

- Due Diligence for Fashion Supply Chains [guide]

- Sustainable Product and Materials Traceability Software [report]

- Isotopic Origin Verification [on-demand webinar]

- The 5 Pillars of Product Traceability: Building Transparent and Resilient Supply Chains [blog]

- 7 Key Principles of Supply Chain Transparency [blog]

- The Science of Trust: Transforming Supply Chains from Source to Story [blog]

- How to Improve Supply Chain Compliance – 8 Key Tactics for Businesses [blog]

(Image credit: Vecteezy)

Oritain’s experienced global team is trusted by many of the world’s leading brands. For more information on how we can help improve your supply chain traceability, contact us today.

Disclaimer: The information provided in this document does not and is not intended to constitute legal advice. Instead, all information presented here is for general informational purposes only. Counsel should be consulted with respect to any particular legal situation.