Since the Uyghur Forced Labor Prevention Act (UFLPA) in the U.S. came into effect in June 2022, its impact has lingered over the fashion and apparel industry, casting long shadows across incredibly complex supply chains, that compel companies to reevaluate and strengthen their supply chain risk mitigation strategies.

More regulations are in the works from the U.S., Canada, and Europe to name a few – to mandate greater environmental, social and governance (ESG) disclosures, documentation and tracking, further amplifying the need for stringent supply chain management.

However, mitigating supply chain risks is not a one-time effort, but rather an ongoing process that requires a comprehensive strategy.

A well-designed supply chain risk mitigation strategy should focus on 3 key pillars:

- Financial nexus

- Identifying forced labor

- Raw material verification

Pillar 1: Financial nexus detection with AI

The first pillar of risk mitigation is understanding the financial nexus in your supply chain and tracing the transactions from your company to suppliers and sub-contractors across multiple tiers. You need to prove that you are not tied to any banned entities at any point in your supply chain.

AI-based tools have become increasingly popular in identifying and managing financial risks. These tools use sophisticated algorithms to analyze large volumes of financial data to identify hidden risks such as indirect connections to banned or unethical entities. They can flag suspicious transactions, especially cash exchanges, and help companies take necessary action to mitigate these risks.

Despite their effectiveness in financial risk management and entity connections, AI tools don’t address where the raw material is truly coming from at a product level. This lack of visibility can leave you vulnerable to supply chain disruptions and potential ethical violations.

AI insights alone without raw material verification can lead to a false sense of security, leaving importers susceptible to being in breach of the laws and regulations for that jurisdiction. Much like building a house on shaky foundations – it may look strong and secure, but it’s only a matter of time before cracks appear.

Pillar 2: Identifying forced labor with mapping & blockchain technologies

Forced labor is a pressing concern in fashion and apparel supply chains. The complexity of these supply chains often makes it challenging to identify forced labor practices, as perpetrators can easily hide behind multiple layers of subcontractors and suppliers.

According to the 2023 Fashion Transparency Index, around $468 billion of garment imports in the G20 are at risk of modern slavery, demanding vigilant and proactive strategies to address it effectively.

Supply chain mapping tools and blockchain technology have emerged as powerful tools in providing point-to-point traceability and transparency into supply chains. Brands and retailers can send questionnaires to facilities involved in shipments, gather information on labor practices and documentation, and assess ESG risks using primary data retrieved through purchase order (PO) numbers.

However, these tools are reliant on vendor declared information and paper-based documents, and paper documents are only as good as what is written on them. They fail to fulfill the crucial requirement of providing assurance on the origin of cotton and what goes into the final garment.

Supplier-provided information may not always reflect on-the-ground realities, so without verifying this through forensic-level testing you could still be at risk of sourcing raw materials produced with forced labor. That means when faced with potential shipment detentions or challenged by a regulator, your evidence may not stand up to scrutiny.

Pillar 3: Raw material verification

The third pillar of an effective risk mitigation strategy in the fashion and apparel industry is raw material verification.

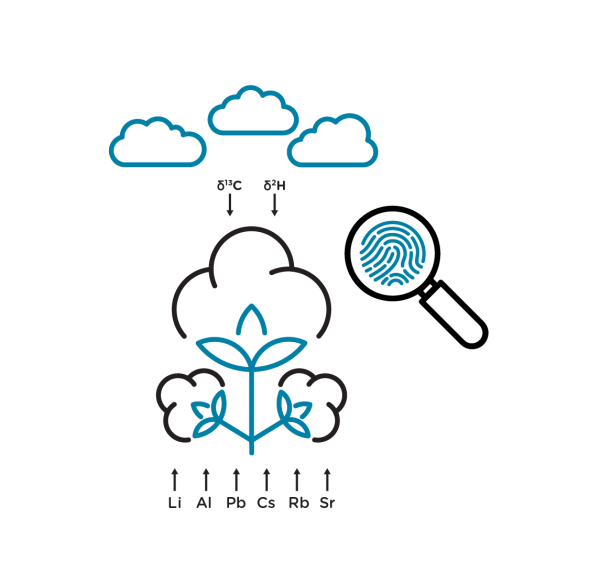

Verifying raw materials such as cotton underpins the capabilities of AI and supply chain mapping tools, necessitating scientific traceability methods like forensic isotopic testing.

Forensic isotopic testing involves analyzing naturally occurring isotopes that exist within the cotton fiber itself and impacted by soil, water, and air. These isotopes are unique to their geographical location and act as a natural fingerprint for the products grown there. By pinpointing the origin of a product, you can proactively prevent it from entering your supply chain and potentially causing harm to your brand's reputation.

Documentation is essential for understanding your supply chain, but it can often be falsified or inaccurate. Forensic isotopic testing acts as a validation and verification tool for paper documentation – ensuring that the product's origin matches what is stated on paper.

U.S. Customs and Border Protection (CBP) has advised that the isotopic testing results can be submitted with other supply chain information to prove no connection to high-risk regions. This means you can use the evidence to prove the authenticity and compliance of your products, protecting your brand's reputation and enhancing consumer trust.

Conclusion

In today’s fast-paced global commerce, the stakes are incredibly high. A shipment detained for 30 or 60 days can have significant economic consequences for a company, potentially resulting in the loss of sales and an even longer-lasting impact on brand reputation.

The future of supply chain management lies in a holistic, multi-faceted approach, where transparency, technology, and forensic verification converge to create resilient supply chains that can stand the scrutiny of regulations like the UFLPA and other emerging laws coming into effect. Companies that embrace this triad will not only thrive in the face of regulatory challenges but will also set new standards of ethical practice and innovation in global trade.

To learn more about how Oritain is helping organizations protect their supply chains and improve their sustainability performance, contact us to speak with one of our team.

Disclaimer: The information provided in this document does not and is not intended to constitute legal advice. Instead, all information presented here is for general informational purposes only. Counsel should be consulted with respect to any particular legal situation.