6 Key Supply Chain Risks (and Remedies) Every Business Must Manage

By Dr. Sam Lind | 18 September 2024

minutes to read.

Supply chains are more than just the mechanism by which you develop products. They’re integral to your brand’s reputation and your business’ success.

Products today are produced in lengthy, often complex, global supply chains. Product integrity is at the mercy of these supply chains. Any weak links risk devastating damage to consumer trust, customer safety, and your bottom line. Knowing how to identify and address these is essential for risk management.

Identifying and addressing the risks isn’t always easy, but it’s better for businesses to operate from a position of knowledge than ignorance. Accept the fact that there will be problems – and introduce effective, data-backed measures to tackle them.

Risks: The Biggest Risks in Supply Chain Management

1. Tainted products

Substituting products for inferior copies, contaminating products with poor-quality materials, and knowingly misrepresenting products are common when businesses lack visibility over their supply chains.

Food fraud is generally carried out by unscrupulous parties for economic gain, and history has provided us with numerous examples of unethical practices. In Oritain’s testing, we continually find products that are mislabeled – where the product itself isn’t true to the label.

Our daily caffeine fix is no exception. Studies have shown the proportion of adulteration in coffee samples, where ground coffee is mixed with corn, soy, barley, and other crops, to be up to 30%.

This does more than corrupt product integrity – it can threaten consumer health. The scandal surrounding contaminated infant milk formula shows the consequences when consumer safety is put at risk.

2. Devalued brand

Poor supply chain processes open the door to inconsistencies and inaccuracies that can cause significant brand damage. If your suppliers use unethical practices or knowingly subvert the law, your brand suffers by association.

Over two-thirds of adults believe that once a brand loses its trust, there’s no gaining it back. 40% of these people go further by trying to dissuade their friends and family to boycott these brands.

Again, we can see examples which bare this risk out. The situation currently playing out with several prominent UK retailers provides a timely cautionary tale. Brand reputation is the victim of operational indiscretion.

3. Loss of revenue

Perhaps the most tangible and immediate risk is loss of revenue. This could be from not having products on shelves or losing access to key markets.

If products are found to not comply with legislation, businesses could face shipments being stopped at the border, product withheld fines being charged, or being unable to import into certain markets.

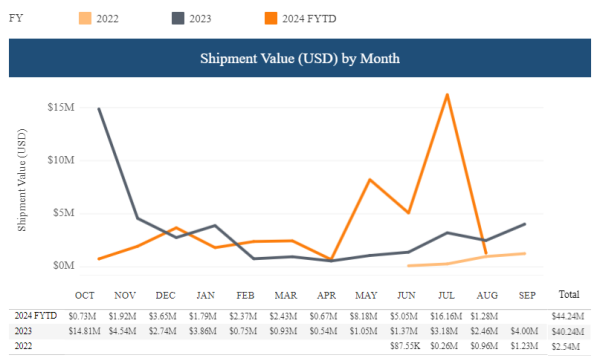

Detainments at the border aren’t just an inconvenience – they are a financial disaster waiting to happen. The latest detention statistics from US Customs & Border Protection (CBP) show that UFLPA enforcement is rising. July 2024 had the highest dollar value of apparel, footwear and textiles shipment detentions since the enactment of the Uyghur Forced Labor Prevention Act (UFLPA), at over US $16 million in that month alone.

The clearest real-world example of this risk is in the fast fashion industry, where increased scrutiny has led to burgeoning compliance costs and falling revenue.

As we see more and more regulations coming into effect that impact upon supply chains, and that increase business compliance requirements, this risk is only likely to rise.

(Source: US Customs & Border Protection dashboard)

Remedies: How Businesses Can Mitigate Supply Chain Risks

1. Mapping and governance

Managing your supply chain means truly understanding it, and that means going further and deeper than just tier 1 suppliers. It means identifying who your suppliers are working with, which areas they operate in, and how their operations are managed.

This is important because certain countries have greater risk of supply chain disruptions and certain products have higher risk of fraud. Any instances of this threaten the integrity of the entire supply chain.

Map out your broader supply chain to establish all the partners involved and the relationships between each. Define their locations of interest, key personnel, employment practices, ESG footprint, and other key information. Formalizing this provides the supply chain transparency you need to quickly address issues that may arise in the future.

2. Setting and managing KPIs

Customers, investors, regulators, and other stakeholders expect certain standards from your business. Assurances of product and service quality, commitments to ethical employment, objectives around reduction of environmental impact, and so on.

The standards you set for your business must be reflected in those of your supply chain partners. Set Key Performance Indicators (KPIs) as quantifiable measures they must adhere to. These should include targets for carbon emissions, schedules for workplace inspections, and formalized sourcing and employment policies.

Breaches on their part put you at risk. Setting and managing KPIs removes any potential for misunderstanding and empowers you to act promptly if remedial actions are required.

3. Auditing and testing

Once you’ve mapped out your supply chain, you trust they’re adhering to your policies. But unless you verify their claims, the policies are largely meaningless – and claims must be treated as invalid and unproven. The days of tick-the-box thinking are in the past. Trust your suppliers, but verify.

Technology today provides the means to accurately test product integrity to identify instances of fraud or associations with unethical practices which could endanger your business.

Scientifically verified traceability, like that provided by Oritain, is robust and accurate enough to help clients operate from the strongest possible position in addressing supply chain issues.

Programs of ad hoc or regular tests and on-site audits are the real game-changers in achieving greater transparency and traceability into your supply chain.

Building Supply Chain Resilience Through Transparency

Oritain's unique forensic science and data analysis enable stronger supply chains by verifying the true origin of products and raw materials. This makes it possible for businesses to identify fraud which could be linked to unlawful or unethical practices.

For example, identifying coffee, leather or timber products that have been sourced through deforestation; or identifying clothing and apparel garments made from cotton sourced using forced labor.

The EU Deforestation Regulation (EUDR) mandates that businesses must specifically geolocate where in the world their raw materials originate from. Science-based origin verification enables businesses to comply with these requirements with scientific precision.

This science in traceability empowers brands to eliminate unethical practices, improve regulatory compliance and operate more sustainably. By securing their supply chain with more robust measures, they help protect natural ecosystems and can assure consumers of their green credentials.

When it comes to effective supply chain management, knowledge is power. Understand the risks, introduce measures to mitigate them, and reap the rewards of continued success.

Find out more about how Oritain can help your organization improve supply chain transparency by speaking with one of our team.

Disclaimer: The information provided in this document does not and is not intended to constitute legal advice. Instead, all information presented here is for general informational purposes only. Counsel should be consulted with respect to any particular legal situation.